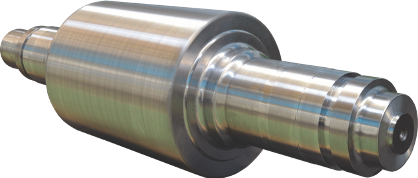

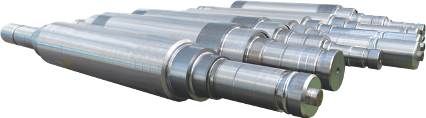

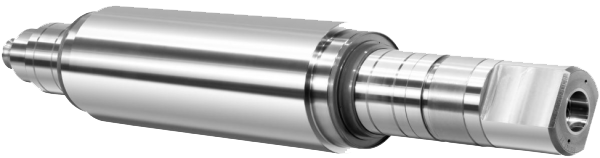

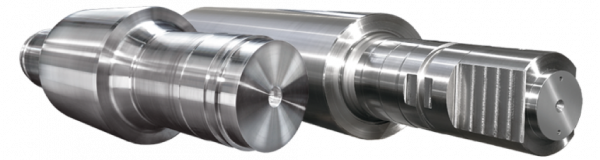

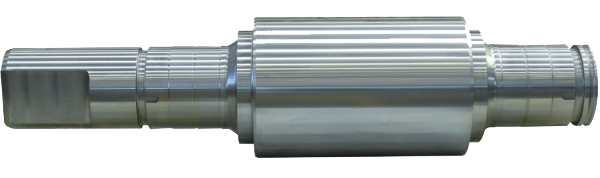

ANADOLUMET Sanayi GmbH is a leading supplier of rolling-mill rolls, steel mill equipment and spares for Steel Plants. We offer our clients the widest range of rolling-mill rolls made by proven and world-known manufacturers for all kinds of rolling mills, accompanied with attractive financing arrangements, end to end logistics and extensive after-sales support.